Nam considered making scale models as a second job and recently turned this hobby into an online business. “My clients are mainly foreigners, most of whom are Japanese because they like collecting handmade products,” Nam said.

Tran Giang Nam with a miniature model. |

It takes from 3 months to 2 years to complete a miniature product because it requires many stages, including finding appropriate materials, processing details, assembling and creating color combinations, Nam said. Not everyone can be a miniature model maker since this work requires patience, diligence and precision. That is why many of Nam’s students give up after a few weeks of trying to learn.

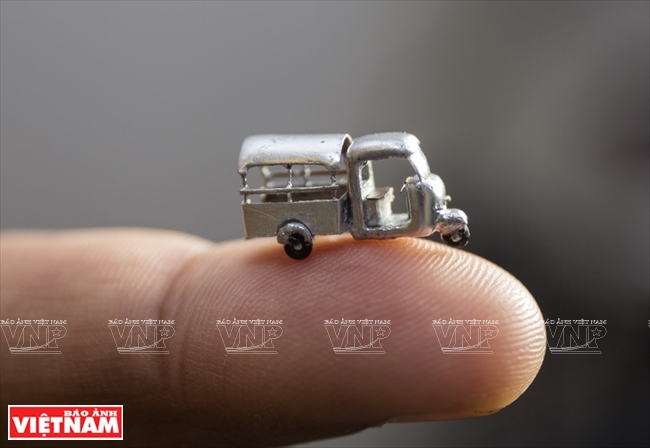

All details of the new models will look like their original objects in every aspect. Fortunately, Nam is blessed with good eyesight so he can see every tiny detail of the products without relying on the support of a magnifying glass. It is Nam’s hard work, high quality craftsmanship and independence from technical aids that have made his products distinctive from the items made by others.

The assembly and shaping process requires a quiet and airtight workplace, Nam said. “Sometimes it was hot, my clothes damp with sweat but I did not dare to turn on the fan because the wind could blow the products away. If any detail was lost, I would have to start all over again.”

Miniature model of an old vespa. |

The materials for making miniature models include copper wire, steel, aluminum, electric circuits, sawdust and composite. Most of these materials, which are “rubbish” from old machines and equipment, became unique and valuable products in Nam’s skillful hands. Nam also uses gold, silver, titanium and other expensive materials to make high-end products designed to a clients’ specifications.

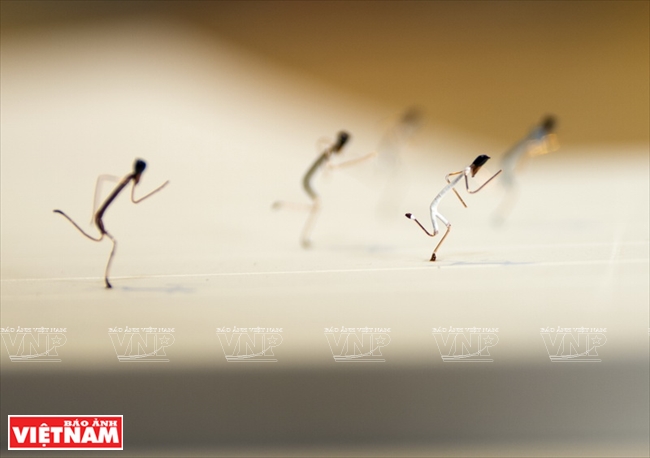

Nam has created 400 millimeter-sized pieces of old cars, airplanes, insects and daily activities. Each product is often priced at 4 million dong (about 200 US dollars). Nam’s most expensive product was a 1954 BMW R51, sold for over 70 million dong (3,000 US dollars).

Nam hopes to create many models associated with the cultural life of the Vietnamese people such as Vietnamese cyclos, traditional long dresses, rice farmers and street vendors because he wants to preserve and introduce the beauty of his homeland to international friends./.